Aspen HYSES Training – ScienceDirect Article – Carbon Capture Process Simulation and Optimization

This Aspen Hyses training presents simulations and optimization of the absorption-based CO₂ capture process using Aspen HYSYS. The heat consumption for desorption is high, and different configurations can be used to reduce energy consumption. This Aspen HYSES course shows the simulation of a standard and vapor recompression process for CO₂ capture.

Download Reference Article: Click Here

Principles for split-stream and vapor recompression

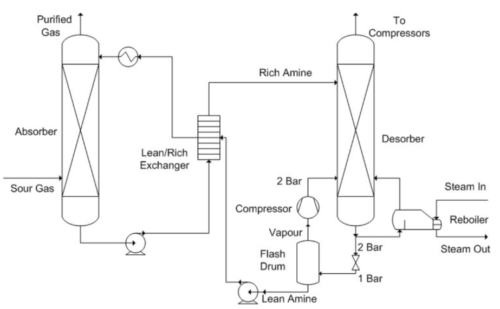

Regenerated amine solution from the desorber bottom is pressure reduced and led to a flash tank (lean amine flash). The liquid from the flash tank is the lean amine stream which is recirculated back to the absorber.

The vapor from the flash tank is compressed and returned to the bottom of the desorber. The vapor recompression produces a regenerated amine with fewer CO₂ which absorbs more CO₂ in the absorber.

Aspen HYSES Tutorial

- Step 1: Simulation of Absorption Column on HYSES

- Step 2: How to Simulate a Pump

- Step 3: Simulation of Distillation tower on Aspen HYSES

- Step 4: Simulation of Heat Exchanger in HYSES

- Step 5: Simulation of a Streams Mixer

- Step 6: How to Converge a Recycle Stream

- Step 7: Optimization of CO₂ Capture process in Aspen HYSES

- Step 8: Simulation of Vapour Recompression Cycle

Step 1: Simulation of Absorption Column on HYSES

A standard amine-based CO2 capture process has a simple absorber and a simple desorber. This simulation of the absorption column achieved 85% and 85 % CO2 removal with 20 stages and a Murphree efficiency of 0.15.

Step 2: How to Simulate a Pump

In this tutorial, you will learn to simulate a pump.

Step 3: Simulation of Distillation tower on Aspen HYSES

In this Aspen hyses tutorial, you will learn to simulate the desorber distillation column and how to calculate the heat consumption of the reboiler.

Step 4: Simulation of Heat Exchanger in HYSES

In this tutorial, you will learn to design a heat exchanger. 5 K minimum temperature difference in the rich/lean heat exchanger was specified for all the simulations in this work.

Step 5: Simulation of a Streams Mixer

In this tutorial, you will learn to mix two streams using the Mixer component in Aspen hyses.

Step 6: How to Converge a Recycle Stream

The most challenging part of any process design simulation is to converge a recycle stream and maintain the composition at the desired level. In this training, you will sharpen your professional skills to simulate the complete plant process.

Step 7: Optimization of CO₂ Capture process in Aspen HYSES

In this aspen hyses course, a regenerated amine solution from the desorber bottom is pressure reduced and led to a flash tank (lean amine flash). The liquid from the flash tank is recirculated back to the absorber. The vapor from the flash tank is compressed and returned to the bottom of the desorber.

Step 8: Simulation of Vapour Recompression Cycle

The heat consumption for desorption is high, and different configurations can be used to reduce energy consumption. This course shows the simulation of a standard and vapor recompression process for CO2 capture.

Need our help or consultation?

If you are seeking a Research Scientist, Data Analyst or require professional services for a complex project, We offer a wealth of experience and skills to deliver programmatic solutions. Contact us on LinkedIn.

Email: support@algorithmminds.com

LinkedIn: https://www.linkedin.com/in/ahsankms/